As the aerospace industry looks toward a greener, more sustainable future, energy solutions have become a critical area of innovation. At Aurora Flight Sciences, a Boeing company, teams in the company’s advanced energy lab play a pivotal role in developing the high-performance energy systems necessary for the next generation of aviation. The lab is equipped with advanced tools and technologies that enable the design, development, testing, and validation of batteries and fuel cell systems tailored specifically for aerospace applications.

Custom Battery and Fuel Cell Development

Batteries play a vital role in aerospace and aviation, powering various capabilities from critical onboard systems to vehicle propulsion. In autonomous electric vertical takeoff and landing (eVTOL) vehicles, such as Aurora’s SKIRON-X small unmanned aircraft system (sUAS), batteries power the entire operation including flight, data transmission, and payload functionality.

Aurora’s energy lab designs custom lithium-ion battery packs that balance high energy density with lightweight construction, allowing SKIRON-X to achieve extended flight times without compromising payload capacity. Today, teams are developing three different batteries to support a variety of needs. SKIRON-X’s standard battery pack features cylindrical cells that provide 224 watt-hours per kilogram (Wh/kg), allowing for a flight endurance of 3.5 hours.

Market forecast by Region, Class, Type, and End-User. Country Analysis, Market and Technology Overview. Opportunities Analysis, and Leading Company Profiles

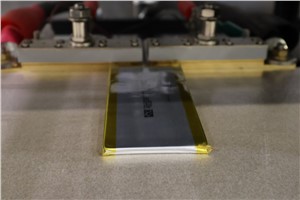

Download free sample pages More informationA prototype battery in development features pouch cells that are more space-efficient than cylindrical cells and provide up to 22% more energy with only a 4% increase in weight. These packs are equipped with a battery management system (BMS) that monitors each cell’s voltage, temperature, and degradation over time, while also balancing cells with uneven aging. This capability enables more accurate predictions of remaining flight time and enhances both battery life and overall safety. Additionally, the performance data collected allows engineers to refine future designs based on real flight experiences.

Engineers are also developing an auxiliary belly-mounted battery specifically designed for the SKIRON-X aircraft. Built in-house, this innovative battery utilizes next-generation anode materials and integrated power conversion to deliver high energy density while maintaining compatibility with the SKIRON-X system. The most recent test of a SKIRON-X outfitted with the prototype pouch battery and the belly-mounted auxiliary battery flew for 5hrs 24min on battery power alone.

The engineering and test team at Aurora continues to push the limits on endurance with both battery-only power and hydrogen fuel cell power. In August, Aurora’s hydrogen-fuel-cell powered SKIRON-XLE achieved a successful seven-hour flight test, marking a significant advancement in flight endurance for the Group 2 platform.

Testing and Validation

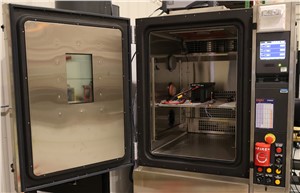

Testing is a cornerstone of Aurora’s approach to battery and fuel cell innovation. The laboratory is equipped with thermal chambers alongside both low- and high-voltage test systems, enabling engineers to simulate real-world conditions at both sub- and full-scale levels. By utilizing actual flight data, Aurora can replicate the power demands of various missions, providing invaluable insights into battery and fuel cell performance under typical operational stresses as well as edge cases.

Using this equipment, the team tests and characterizes new battery cells and technologies, comparing their “as-tested” performance to their “as-advertised” specifications. Aurora programs can then leverage this database to guide battery development decisions. Beyond the cell-level, the lab has successfully evaluated a diverse range of hardware—from hydrogen fuel cells for sUAS to 1,000-volt battery strings for air taxis—ensuring these systems are ready for integration and flight testing.

Another critical asset in Aurora’s energy lab is the Ultra-High Precision Coulometry (UHPC) system, which allows teams to rapidly test electrochemical processes within batteries and other electrochemical systems across various form factors. This system provides industry-leading precision and accuracy for battery chemistry selection and the development of highly accurate predictive models.

Safety remains a top priority at Aurora. The lab conducts rigorous certification tests, including those mandated by the Radio Technical Commission for Aeronautics (RTCA) DO-311 Minimum Operational Performance Standard (MOPS) for Rechargeable Lithium Batteries and Battery Systems. Engineers assess thermal runaway, arc flash, and environmental stress to ensure the batteries meet the highest operational standards.

Aurora’s energy lab is a cornerstone of the company’s mission to advance the future of flight. While the aerospace industry continues to move toward a greener future, Aurora teams are laying the groundwork for future innovations in sustainable energy storage.