Project: INVENTOR (Innovative design of installed airframe components for aircraft noise reduction)

Aircraft noise is generated by the engines and the airframe, with the latter primarily coming from the landing gears and high-lift devices. The INVENTOR project aims to understand the physics of airframe noise generation in business jets and short- to medium-range transport aircraft, with the goal of reducing aircraft noise using numerical simulations, validated through aeroacoustic experiments.

The challenge

The project targets reductions in noise levels from installed landing gears and high-lift devices during landing and approach. Specifically, the aim is to achieve reductions of 2-3 dB(A) and 1 dB(A), respectively. This is a key stepping stone towards achieving the ACARE Flightpath 2050 goal of cutting perceived aircraft noise levels by 65%.

Market forecast by Regions, Aircraft type, and Ownership type. Country Analysis, Market and Technology Overview, Critical Raw Materials, Opportunity Analysis, and Leading Company Profiles

Download free sample pages More informationThe solution

In order to gain a deeper understanding of airframe noise generation, high-fidelity numerical simulations were conducted in conjunction with aeroacoustic wind tunnel experiments. Two approaches were adopted to reduce airframe noise:

What did we do?

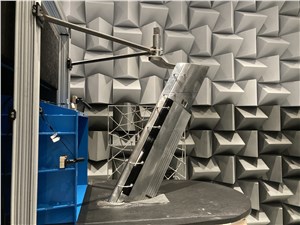

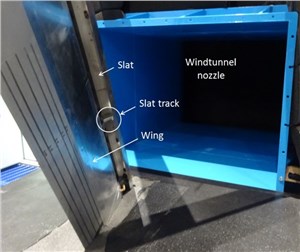

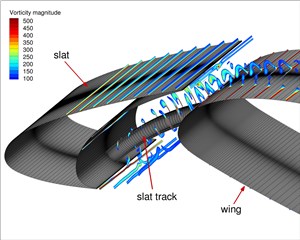

NLR focused on the noise generated by the deployed wing slats, which largely originates from the slat tracks that attach the slats to the wing. Based on numerical flow simulations, a low-noise slat track was designed using a tilted fairing to reduce flow separation. A range of slat track designs was then tested in NLR’s acoustic wind tunnel, showing a potential reduction of slat track noise by 5 to 10 dB. Finally, high-fidelity numerical simulations of slat-track noise generation were carried out and successfully validated with wind tunnel data.